Plateau Excavation

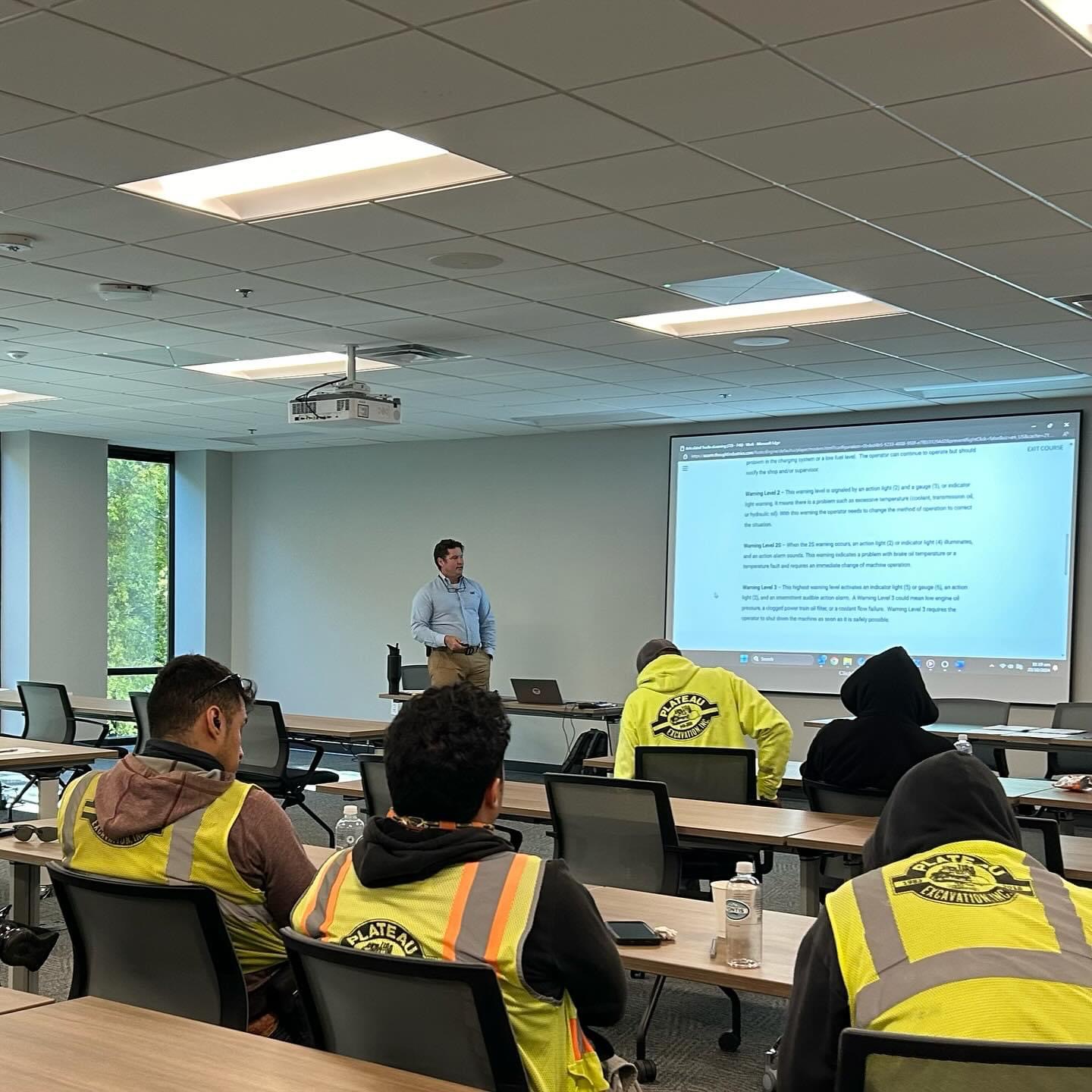

Building Better Operators: Inside Plateau Excavation’s Training Program

At Plateau Excavation, we believe our people are our greatest asset. The strength of our fleet is important — but the skill, discipline, and decision-making of the operators behind the controls is what truly drives performance.

That’s why we’ve built a comprehensive Heavy Equipment Operator Training Program designed to elevate safety, efficiency, and long-term equipment performance across every jobsite.

Led by Industry Expertise

Our training program is led by Andrew Field, Director of Training since May 2024. With more than 45 years of hands-on experience operating nearly every machine in the Caterpillar lineup across a wide range of applications, Andrew brings unmatched real-world knowledge to operator development.

From 2006 forward, Andrew worked directly with Caterpillar Inc. in Illinois, helping develop course materials and certification structures for Levels 1 through 3. Through the University of Illinois Caterpillar Instructor Accreditation Program (CIAP), he earned instructor-level certifications across nearly all machine families and has delivered Caterpillar training worldwide for two decades.

His specialized credentials include:

-

DOSIM (Bulldozer Operation Study and Improvement Method)

-

Earthmoving Fundamentals

-

Fuel Optimization & Performance

-

Wheeled Tractor-Scraper Best Practices

-

Application-specific performance studies

This depth of expertise ensures our program is built on proven principles — not theory.

A Data-Driven, Field-Focused Approach

Plateau’s operator training is not generic. It is tailored specifically to our fleet and jobsite demands using:

-

VisionLink fault code data

-

Field performance observations

-

Maintenance trends and insights

-

OSHA 30-influenced safety standards

We focus on solving the most common operational challenges that impact uptime, fuel consumption, component wear, and overall productivity.

The objective is simple:

Safer operators. Longer-lasting equipment. Stronger performance.

Core Components of the Program

Level 1 Operator Training

Our Level 1 course is delivered as an 8-hour weekly class offered in both English and Spanish. Nearly 1,000 operators have completed Level 1 in the past two years.

The curriculum covers:

-

Machine fundamentals

-

ISO symbol interpretation

-

Warning system response and troubleshooting

-

Component identification

-

Safe mounting and dismounting procedures

-

Fire prevention

-

Best operating practices

-

Techniques to reduce downtime, fuel usage, and ground-engaging tool wear

Operators gain a deeper understanding of how their actions directly impact equipment longevity and jobsite efficiency.

Detailed Machine Walkarounds

Each machine family receives customized walkaround training. Operators learn how to identify key components, recognize early signs of wear, and conduct thorough pre-shift inspections.

This hands-on familiarity builds confidence while preventing avoidable mechanical failures.

In-Field Corrective Coaching

Training doesn’t stop in the classroom.

Our team provides weekly on-site coaching, addressing operator-induced fault codes with immediate, personalized instruction. By tying real data to real behavior, we help operators correct issues before they become costly problems.

Simulator-Based Skill Development

Plateau utilizes three Caterpillar simulators — an articulated truck, a medium excavator, and a mid-sized dozer.

Simulators allow us to:

-

Evaluate new hires

-

Train operators transitioning between machine types

-

Improve control precision and timing

-

Reinforce component knowledge

-

Create realistic, risk-free training scenarios

Simulation enhances skill development without putting equipment or crews at risk.

eLearning and Video Resources

Our program integrates Caterpillar eLearning modules and a growing internal video library of more than 30 short instructional videos in English and Spanish.

These tools reinforce classroom concepts and provide quick-reference training directly in the field.

Ongoing Professional Development

Every member of our training team holds OSHA 30 certification. Andrew maintains an industry-focused reading list, and Plateau supports annual seminar attendance to ensure our program evolves alongside new technologies and safety standards.

Continuous improvement is not optional — it’s expected.

The Results

This comprehensive approach delivers measurable impact:

-

Reduced downtime

-

Lower maintenance and repair costs

-

Improved fuel efficiency

-

Extended component life

-

Stronger operator confidence

-

Safer jobsites

Most importantly, it reinforces Plateau’s commitment to operational excellence and responsible heavy equipment management.

Always Moving Forward

At Plateau Excavation, developing skilled operators is more than a training initiative — it’s a strategic investment in our people, our equipment, and our clients.

Because in heavy civil construction, performance starts in the seat.

And we’re committed to building the best operators in the industry.

Always Moving Forward.